Most of the last few days of activity has concentrated on putting in the services; water, drainage and conduit for electricity and telephone.

In addition, all the joints have been pegged with oak dowells. As expected the oak is continuing to move a little bit but as it shrinks it will pull all the joints very tight.

Driving in an oak dowell. The dry weather of the last few weeks has been ideal and it is a great relief to get to this point having completed all the works that could have caused a potential mudbath!

Suffolk Wildlife Trusts Property and Projects Manager Steve Aylward reveals the trials and tribulations of building an innovative new green education centre at our Bradfield Woods reserve...

Thursday, 31 March 2011

Thursday, 24 March 2011

Foundation structure nears completion

Lots of progress this week with the foundation structure all but completed. The big debate of the last couple of days has been how to make the underside of the building rodent-proof. It looks like the underside will have to be covered with a perforated (3mm holes) galvanised metal sheet unless there is a better alternative.

As the timbers each weigh over 500 Kg a small excavator was used to move them into position.

One of the joints on a ground beam. The beams have been leveled on a bed of lime mortar. As an added precaution to help preserve the timber, the beams have been coated with a 'wash' of hydraulic lime on the underside and on the surface of the joints.

The folding wedges have been made from seasoned beech.

Driving in the wedges.

The almost completed foundation 'grid'. All that is left to do is peg the joints with 20mm oak dowels.

As the timbers each weigh over 500 Kg a small excavator was used to move them into position.

One of the joints on a ground beam. The beams have been leveled on a bed of lime mortar. As an added precaution to help preserve the timber, the beams have been coated with a 'wash' of hydraulic lime on the underside and on the surface of the joints.

The folding wedges have been made from seasoned beech.

Driving in the wedges.

The almost completed foundation 'grid'. All that is left to do is peg the joints with 20mm oak dowels.

Monday, 21 March 2011

Breaking the ground

Most of the joinery on the the foundation timbers is now complete and the next stage is to start placing them in position.

While some of the cuts for the joints are made using either a circular saw or small chainsaw, much of the hard work is still done with a chisel.

The ground bearing beams will sit on a shallow bed of crushed stone. The Building Inpsector dropped by today and approved the first foundation trench.It is quite refreshing that less conventional foundations such as ours are approved on the grounds of common sense backed up by sound design.

Moving the first of the four ground bearing beams into position To make up a total length of 9.1m, two pieces of timber have to be joined using a type scarf joint. The hope is that all four ground bearing beams will be in place by the end of the week.

The ground bearing beams will sit on a shallow bed of crushed stone. The Building Inpsector dropped by today and approved the first foundation trench.It is quite refreshing that less conventional foundations such as ours are approved on the grounds of common sense backed up by sound design.

Moving the first of the four ground bearing beams into position To make up a total length of 9.1m, two pieces of timber have to be joined using a type scarf joint. The hope is that all four ground bearing beams will be in place by the end of the week.

Thursday, 10 March 2011

Work begins on site

Canham Builders have now arrived on site and are constructing a temporary covered work area. This will provide shelter for all the joinery work starting with the huge foundation timbers.

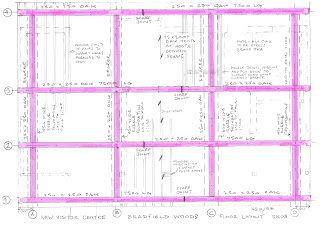

The foundation design is shown below. The 250mm square oak bearers will be joined using scarf joints. These use folding wedges - a pair of triangular shaped oak wedges which when driven into the joint from either side pull it tight.

The oak bearers will lie on the ground on shallow trenches filled with crushed stone. A bed of lime mortar will be used to level the bearers.

A second row of 250mm square oak beams will then be fixed at 90 degrees to create a rigid grid structure. These beams will also be jointed and again use folding wedges to pull the joint tight.

The floor joists will then sit between these beams adding further rigidity to the entire structure.

The foundation design is shown below. The 250mm square oak bearers will be joined using scarf joints. These use folding wedges - a pair of triangular shaped oak wedges which when driven into the joint from either side pull it tight.

The oak bearers will lie on the ground on shallow trenches filled with crushed stone. A bed of lime mortar will be used to level the bearers.

A second row of 250mm square oak beams will then be fixed at 90 degrees to create a rigid grid structure. These beams will also be jointed and again use folding wedges to pull the joint tight.

The floor joists will then sit between these beams adding further rigidity to the entire structure.

Subscribe to:

Comments (Atom)